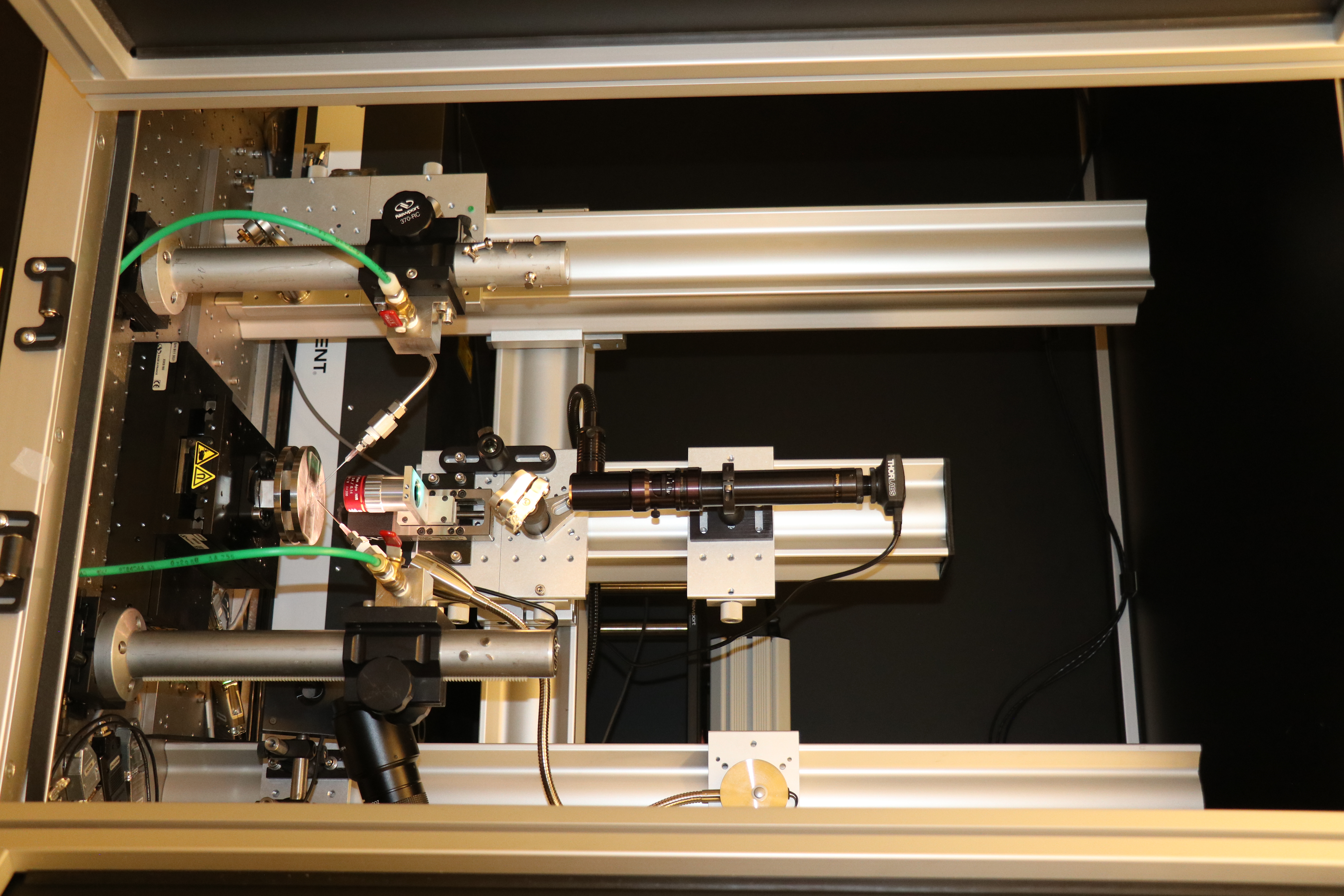

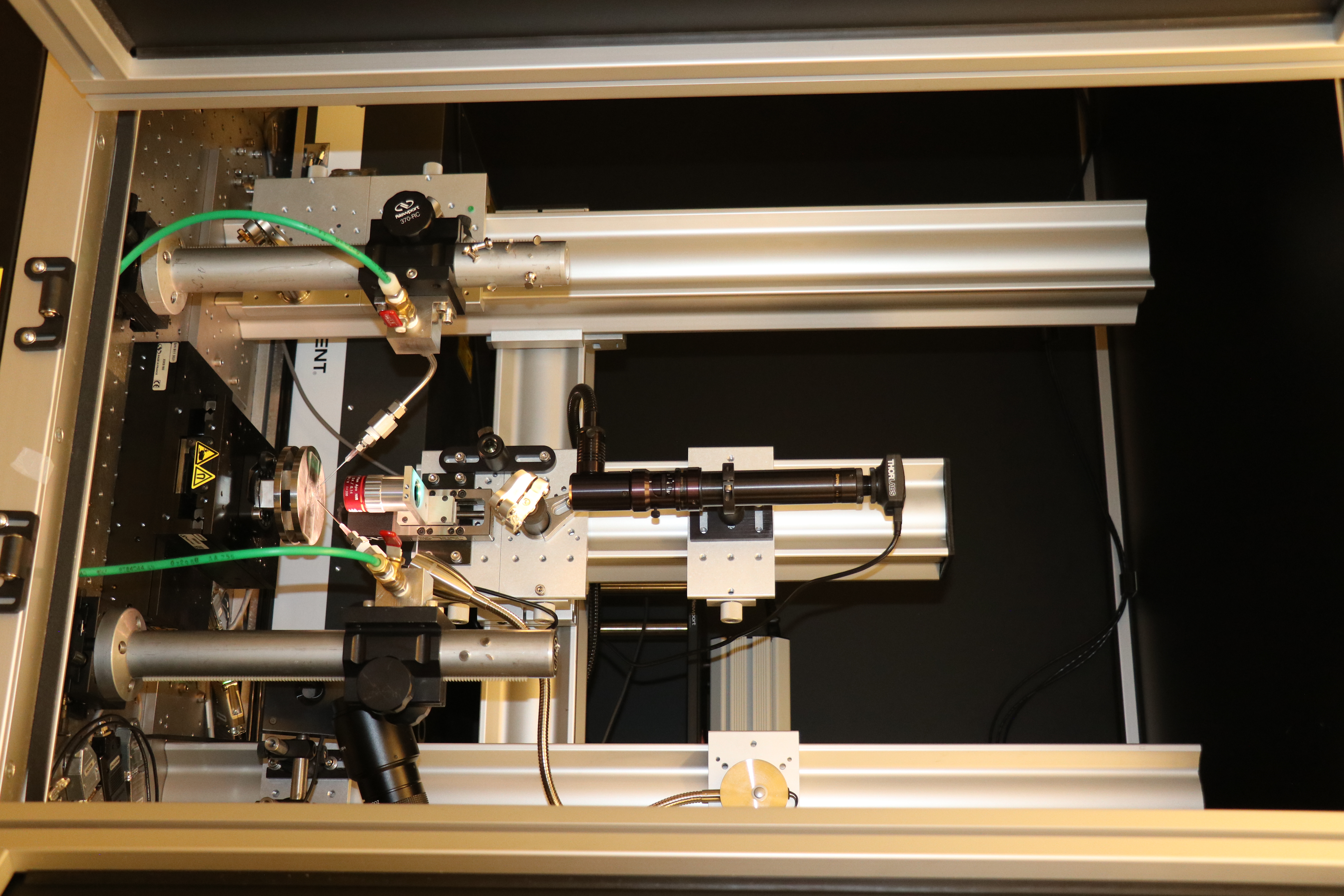

FemtoScribe uses femtosecond optical pulses that are shorter in duration than a substrate’s electron-phonon thermalization time. As a result, the system can ablate material with very little unwanted heat damage, allowing for the machining of features down to the nanoscale. An additional benefit of the system’s short pulses is that they possess extremely large instantaneous peak power, well above tens of MW. Such extreme peak power allows for the non-linear, multi-photon ablation of virtually any material and alleviates the need to consider the absorption wavelength of the substrate while machining.

Capabilities include:

- Machining of microchannels in quartz, metal, and polymers for microfluidic chip assemblies.

- Fabrication of microscale pillars and tensile specimens for nanomechanical testing.

- Selective removal of thin films without damaging the supporting substrate (e.g., removal of thin-film Au from a quartz substrate).

- Machining of thin-film superconducting electrical bridges.

- Machining through-masks with a minimum 50 um feature size.

- Machining optical masks with a minimum 500 nm feature size.

- Writing of waveguides and optical Bragg gratings in bulk glass via point-by-point index of refraction modification.

Laser specifications:

- Coherent Monaco diode-pumped industrial femtosecond laser

- Variable pulse duration <350 fs up to > 10 ps

- Up to 80 µJ/pulse at 750 kHz, 1035 nm wavelength

- 40 µJ/pulse at 750 kHz, 517 nm wavelength

- Single-shot to 1 MHz pulse rates possible

Contact: Chris Sheehan