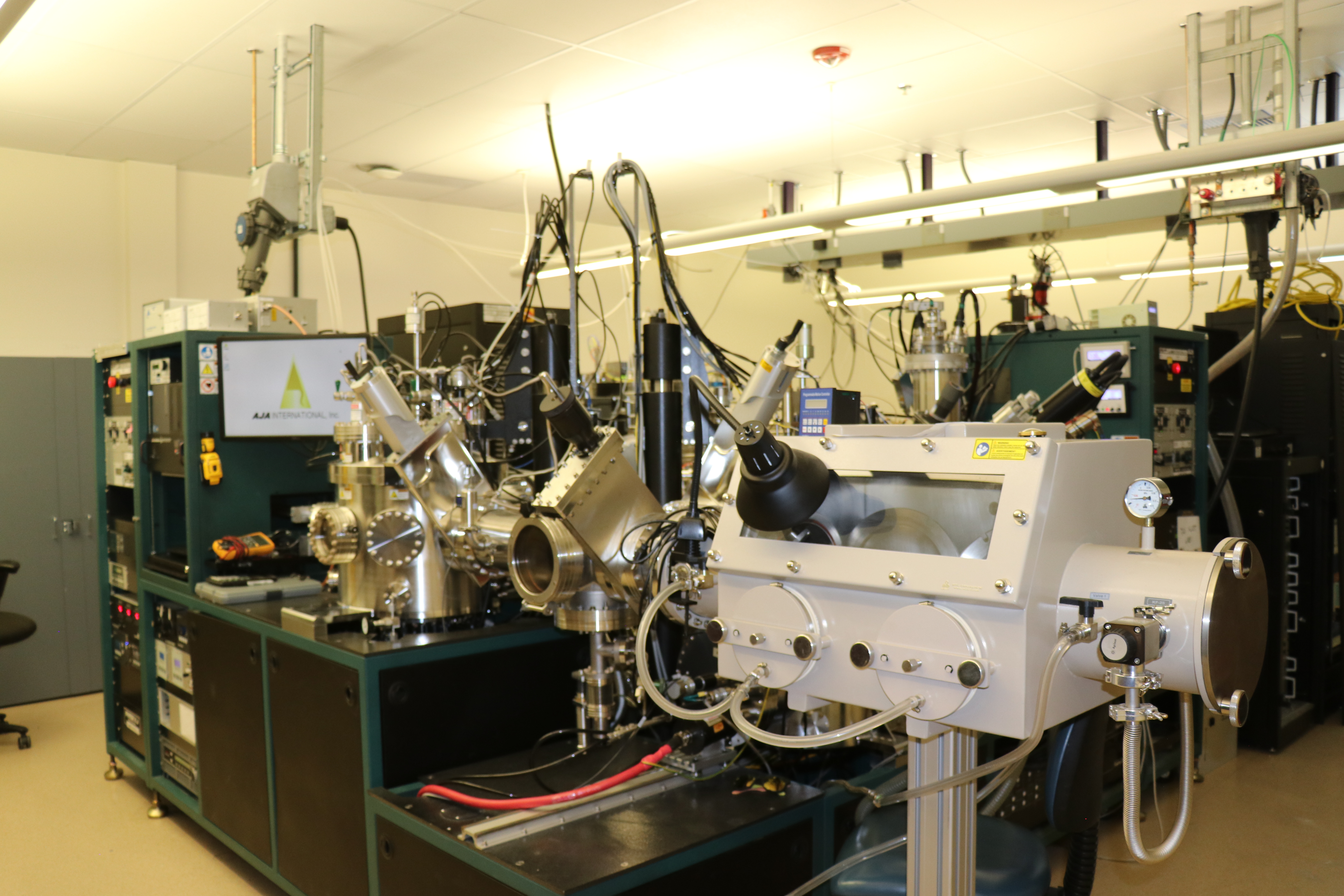

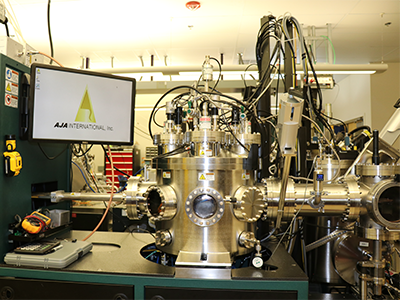

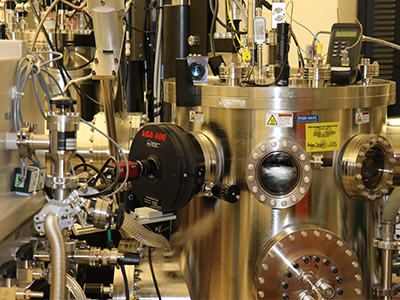

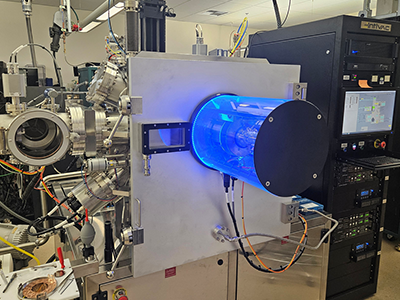

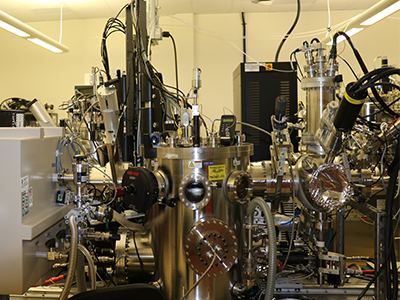

Four physical vapor deposition chambers (2 multi-magnetron sputtering, 1 E-beam, 1 dual ion beam sputtering, and 1 dual E-beam evaporator) allow our scientists and users to deposit novel materials including complex oxides, strain engineered multilayers, graded high entropy alloys, and thick epitaxial films. Heated and biased stages allow for intimate control over several microstructural features such as texture, density, chemistry, and grain size. A new HiPIMS unit will allow for dense metallic and nitride thin films. In-Situ growth diagnostics including a laser curvature tool, surface acoustic wave (SAW), and RHEED monitoring systems, measure internal stress, modulus, and crystallography of films as they are being grown.

Capabilities include:

DC Magnetron Sputtering

Dual Source E-Beam Evaporation

Dual Ion Beam Sputtering and Etching

Characterization Chamber (XPS, Auger, SEM, XRF, Profilometry)

Contact:

Chris Sheehan

Research Highlight:

Effects of Substrate Temperature and Deposition Rate on the Phase Separated Morphology of Co-Sputtered, Cu-Mo Thin Films

Derby, B.; Cui, Y.; Baldwin, J. K.; Misra, A. Thin Solid Films 2018, 647, 50–56. DOI:10.1016/j.tsf.2017.12.013.